May 29,2024

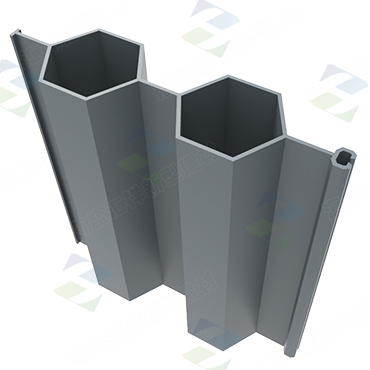

The latest plastic piling sections have a 50+ year design life and are highly corrosion resistant. They are also more economical than steel alternatives and require minimal maintenance.

Durability

Unlike steel sheet piles, vinyl piling is impermeable and does not swell in water. This makes them a good choice for applications that require long-term usage. Additionally, they are resistant to corrosion and can withstand extreme weather conditions. Your pipe and pile supply contractor can help you determine the best option for your project.

Vinyl sheet piles are also environmentally friendly. They are made of recycled materials and can last up to 50 years. They can be used in construction projects such as bridge foundations, retaining walls and canals. They can also be used in breakwater walls, cut-off walls and sealing cofferdams.

ESC’s research has shown that the environmental impact of vinyl piling is significantly lower than that of steel sheet piles. The results of the analysis were based on a cradle-to-site approach (extending the cradle-to-gate approach with transport from the manufacturer to the waterfront construction site). For all damage categories, the share of impact resulting from transportation did not exceed a few percent.

Environmentally friendly

Plastic sheet piles are environmentally friendly and can be installed in dense granular soils. They are also resistant to corrosion, weathering, and pest infestation. They can last up to 50 years and require no special maintenance. They are also a great alternative to concrete and steel.

Compared to traditional concrete and steel sheet piles, plastic piles are less expensive to install. They can be used in a wide range of applications including water control structures, bulkheads, and flood defenses. Unlike steel sheet piles, plastic sheet piles do not rust and do not need periodic coatings or sacrificial anodes to protect them from corrosion.

In addition, plastic sheet piles are environmentally friendly and can be easily reused. The construction process is mechanized and requires minimal disruption to the surrounding environment. The sheets are laid out in sections and hammered in with vibratory or impact hammers. This technique is especially useful in rocky or difficult soils and can save time and money.

Cost-effective

The construction of a sheet pile wall can be completed much faster than the traditional large concrete slope protection dike. This makes it more cost-effective and environmentally friendly. It also has good sealing characteristics. In addition, it can be recycled after use.

The material used in the production of vinyl pilings is a poly vinyl chloride (PVC), which resists weather influences and has a long service life. It is also more durable than steel or concrete.

Unlike wood, which may have a number of imperfections and deformities, vinyl pilings are made to precise standards, and have a clean and aesthetic design. This makes them ideal for projects with a high degree of visibility.

Another advantage of vinyl piles is their ability to be driven in most soil conditions. In rocky soils, driving can be assisted by using high-pressure air or water jetting. In cases where the ground is too rocky for driving, digging is the next option.

Easy to install

Vinyl sheet piles are a new option that has many benefits over traditional steel or concrete piling. They are extremely durable and have a long service life. They are also resistant to natural weather influences and rodents. They do not require further maintenance such as painting or pressure treating, which saves on cost.

English

English 中文简体

中文简体